If your business operates in and around metropolitan NSW, then you might have a need to engage laser cutting in Sydney. This is especially true if you are a business that needs good printing services and cutting pieces of material in a highly precise and efficient manner.

However, this technology can be difficult for the uninitiated to wrap their heads around and it never hurts to get a little more education on something before you invest in it. Let’s take a look at some useful information you should be aware of before you go looking for laser cutting in Sydney.

So, what it is exactly?

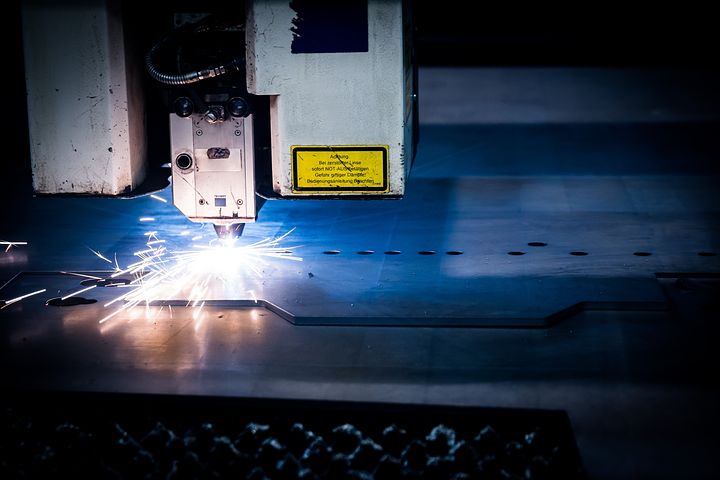

All laser cutting in Sydney, in the most simple of terms, makes use of a highly focused beam of light in order to precisely separate materials like steel, glass, plastic, silicon, wood and glass.

In the early days of this technology, mirrors were primarily used in order to direct and focus the beam, but nowadays it is far more likely when you encounter laser cutting in Sydney the unit will be making use of fibre optic lenses.

The lens is used to funnel the light so that it is so highly focused that it’s able to burn through the material it is being used on.

In broad terms, there are two varieties of this technology that you will come across: fusion and ablative.

Fusion works to melt the material in a column and shears away the molten material with a high pressure gas stream. Ablative uses a pulsed beam to cut away material one layer at a time, which is comparable to chiselling stone except in a much more precise way.

What materials can be used?

If you’re looking at engaging laser cutting in Sydney then it’s useful to know exactly what kind of materials can and can’t be used. As mentioned earlier, the most common accepted materials come in the form of steel, glass, plastic, silicon, wood and glass.

But there are several materials that you should NEVER put inside the unit, such as polycarbonate sheets which can produce an unpleasant smelling, thick smoke when the beam makes contact.

Cardboard and paper sheets are obviously a big no-no as these materials as the high heat intensity of the beam will cause the material to catch alight very quickly. The fact that this combustion is occurring in and around electrical equipment makes it even more dangerous.

Why should you use laser cutting in Sydney as opposed to other methods?

The primary benefit of using laser cutting in Sydney is that it’s simply far more accurate than other methods of similar cost. This is because the technology that governs the precision of the beam has improved drastically over the years which mean highly detailed pieces, like artwork, can be created in record time and on a mass scale.

Add to that: it is also a lot cheaper per capital when compared with other methods, especially if you invest in getting your own unit to use in-house. After some time, the system will pay for itself in all of the money you’ll save because of its impressive efficiency.

Finally, it is simply a lot faster than other alternatives. This is obviously a big advantage when you need to complete an order quickly and can’t afford for any mistakes to be made.

As you can see, taking advantage of laser cutting in Sydney doesn’t have to be a daunting or confusing process once you educate yourself on the basics. Hopefully you will be able to effectively engage with this awesome piece of technology so that your enterprise can reap the rewards.